product description:

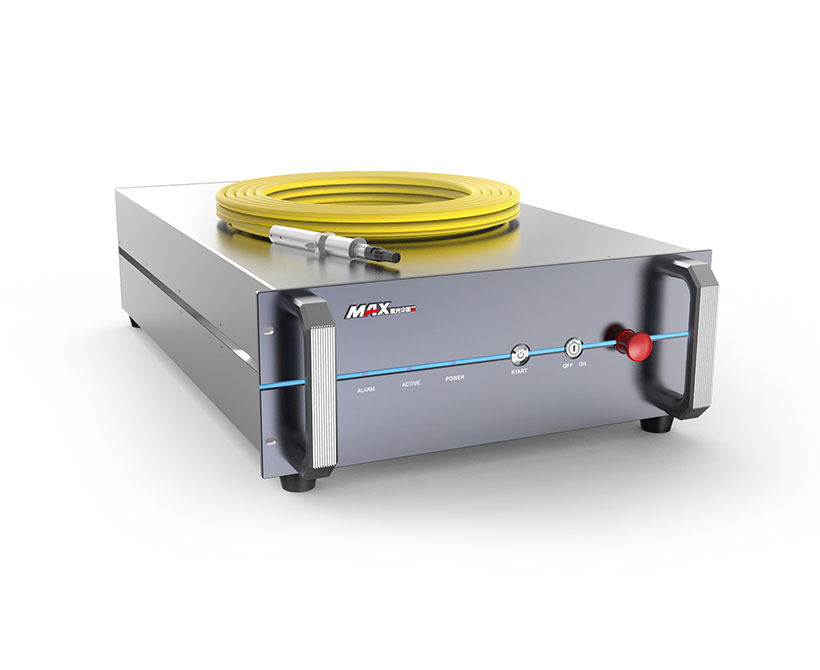

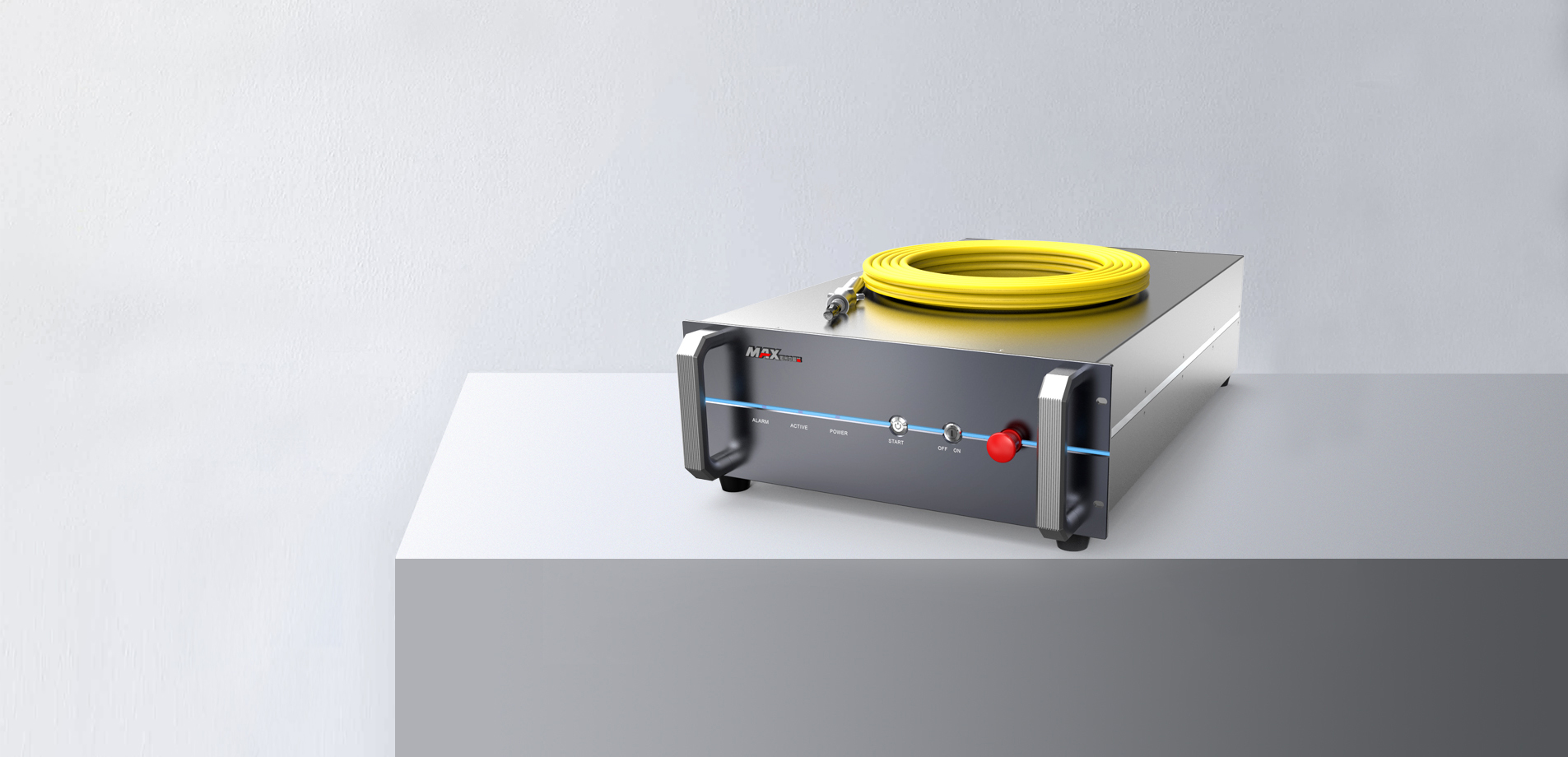

MAX 1000W /1500W single wavelength direct semiconductor laser

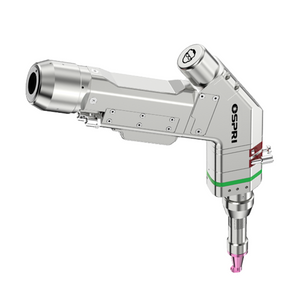

Suitable for welding, cladding, brazing and surface heat treatment of metal materials.

Product Description:

HDLS high-power fiber-coupled semiconductor laser system has higher electro-optical conversion efficiency, more compact size and more competitive price than fiber laser. The laser is output through a conductive fiber, which is suitable for use with automation equipment to realize flexible laser processing. These features make the HDLS high-power fiber-coupled semiconductor laser system perfect for applications such as cladding, brazing, and surface heat treatment of metallic materials.

Compact structure

Small size, light weight, saving installation space

High electro-optical conversion efficiency

Electro-optical conversion efficiency> 45%, energy saving and environmental protection

Sealed structure

Fully sealed structure, dust-proof and moisture-proof, to ensure long-term operation of the machine

Low overall cost

Low cost and low operating energy consumption

Wide range of applications

Suitable for welding, cladding, brazing and surface heat treatment of metal materials

Industry application:

shipbuilding

Ship laser cleaning, hull laser cutting/welding

Rail

Track corrosion laser cleaning, track parts cutting, track joint welding

Equipment

Equipment parts cutting, laser cleaning equipment stains, equipment parts welded together

car

Car painting laser cleaning, repainting, body welding, body cutting, car interior control interface/button marking

Power grid

Laser cleaning the garbage bags on the kite/wire, laser cleaning the oxide layer of the power station equipment

semiconductor

Stainless steel pipe welding

Stainless steel kettle welding

Stainless steel kettle fittings welding

Gas nozzle sealing welding

Kettle base welding

| Models | MD-1000W | MD-1500W | MD-2000W | MD-2500W |

| OPTICAL SPECIFICATIONS |

| Nominal Power | 1000W | 1500W | 2000W | 2500W |

| Mode of Operation | CW/Modulated |

| Polarization | Random |

| Power Tunability | 10 to 100% |

| Wavelength | 920 ± 10 nm

975 ± 10 nm |

| Power Stability | ±1 % |

| Laser Beam Quality, BPP | 20~22 mm*mrad(200μm)

25~28 mm*mrad(300μm)

30~33 mm*mrad(400μm) |

| Modulation Frequency | ≤20 KHz |

| Preview red light power | 150 μW |

| FIBER DELIVERY SYSTEM |

| Interface | QBH |

| Length | 15m standard, other lengths optional |

| Diameter | 200 μm | 300 μm | 400 μm |

| Bending Radius | 200 mm |

| ELECTRICAL RATINGS |

| Supply Voltage | 380 VAC |

| OTHER SPECIFICATIONS |

| Operating Temperature | +10 to +40℃ |

| Storage temperature | -10 to +60℃ |

| Humidity | 10 to 85% |

| Cooling Method | Water Cooling |

| Cooling Medium | Distilled water/ Glycol Antifreeze |

| Dimension | 800×482.6×192 mm |

| Weight | 58(±3) kg

|