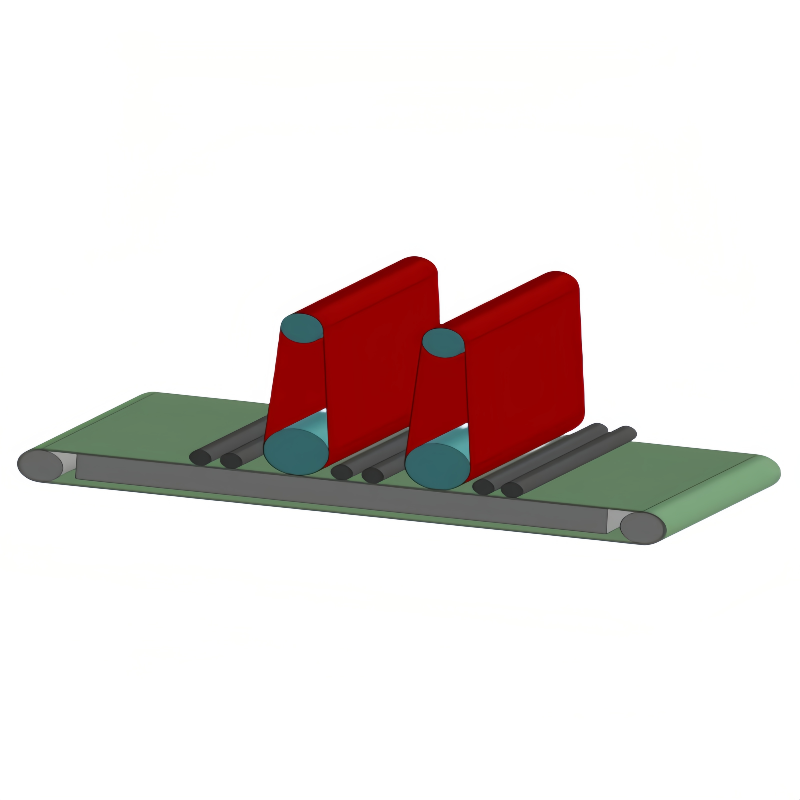

RR4240 Wide Belt Wet Sanding Machine

RR4240 Double-Head Wet Wide Belt Sander

High-Performance Wet Belt Sander for Industrial Metal Finishing

The RR4240 Double-Head Wet Wide Belt Sander is an advanced metal finishing machine designed for precision deburring, oxide removal, polishing, and surface finishing. Equipped with two powerful sanding heads and a wet grinding system, this machine offers unparalleled performance in processing various types of metal surfaces, such as stainless steel, aluminum, and carbon steel. It is ideal for handling parts that have been laser-cut, plasma-cut, or sheared, providing superior results in applications requiring smooth, uniform surfaces with minimal burrs.

Key Features:

Double-Head Configuration:

The RR4240 features a dual sanding head design, which enables efficient multi-stage processing in one pass. The top and bottom sanding heads can be equipped with different abrasives, such as belts or brushes, to carry out tasks like deburring, polishing, and oxide removal simultaneously, optimizing productivity and reducing the need for multiple machines.

Wet Grinding System:

The wet grinding system helps to cool down the workpieces during processing, preventing heat buildup that can lead to part distortion or discoloration. Additionally, it significantly reduces dust emissions, providing a safer working environment and improving overall process efficiency. The water-based solution not only cools but also lubricates the sanding process, extending the life of abrasives and minimizing wear.

High Precision and Consistency:

With precise control over sanding pressure, speed, and feed rate, the RR4240 ensures consistent surface finishes across various materials. The machine’s ability to adjust settings allows for custom applications, ranging from light sanding to heavy material removal, ensuring versatility in handling different production requirements.

Heavy-Duty Build Quality:

Designed for industrial use, the RR4240 features a robust frame and components that can withstand the rigors of continuous production. Its solid construction ensures stability during high-speed operations, minimizing vibrations and maintaining a high degree of accuracy in processing. This heavy-duty design also enhances the machine's longevity, making it a reliable investment for long-term production.

Versatile Applications:

The RR4240 is suitable for a wide range of applications in industries such as metal fabrication, automotive manufacturing, aerospace, and more. It is particularly effective for handling parts with intricate geometries, large flat surfaces, or those requiring specific thickness tolerances. Some typical applications include:

Deburring: Removing burrs from laser, plasma, or flame-cut edges to improve safety and product quality.

Oxide Removal: Efficiently removing oxide layers that form on metals during thermal cutting processes.

Polishing: Achieving a smooth, brushed, or satin finish on stainless steel, aluminum, and other metals.

Edge Rounding: Rounding sharp edges for both aesthetic purposes and enhanced safety in finished parts.

Technical Specifications (Sample Configuration):

| Parameter | Specification |

| Max. Working Width | 400mm |

| Max. Working Height | 60mm |

| Min. Part Length | 150mm |

| Abrasive Belt Size | 1520mm × 400mm |

| Main Motor Power | 7.5 kW (per sanding head) |

| Feeding Motor Power | 1.5 kW |

| Belt Speed | 15–30 m/s (adjustable) |

| Feed Speed | 0.5–6 m/min (adjustable) |

| Water Pump Power | 0.75 kW |

| Machine Dimensions (L×W×H) | 2400 × 1500 × 1800 mm |

| Machine Weight | Approx. 1500 kg |

Benefits of the RR4240 Double-Head Wet Wide Belt Sander:

Improved Surface Quality:

The wet grinding system and dual sanding heads work together to deliver a high-quality, uniform surface finish. The machine can process a variety of materials with consistent results, reducing the need for manual finishing.

Increased Efficiency:

With its dual-head configuration, the RR4240 enables faster processing by handling multiple steps at once. The machine’s high feed speed and adjustable settings allow for optimal throughput, making it ideal for high-volume production environments.

Enhanced Safety and Cleaner Operation:

The water-based system reduces airborne dust, promoting a cleaner working environment and minimizing health risks for operators. The wet system also prevents metal parts from overheating, reducing the risk of damage and ensuring the integrity of finished products.

Customizable for Various Applications:

The RR4240 offers a high degree of flexibility in terms of abrasive material, sanding pressure, and speed. Whether you're working with thin sheet metals or thicker parts, the machine can be fine-tuned to meet specific processing needs.

Low Maintenance and Long Service Life:

Built with high-quality materials and advanced engineering, the RR4240 requires minimal maintenance and offers a long service life. The robust design ensures reliability in demanding industrial settings, making it a cost-effective solution for businesses in need of long-term production capabilities.

Applications in Various Industries:

Metal Fabrication:

Ideal for finishing parts such as panels, brackets, and structural components. The machine handles both large and small metal parts with precision.

Aerospace Industry:

Used to finish high-precision components such as turbine blades, airframes, and brackets that require flawless surfaces and tight tolerances.

Automotive Industry:

Efficient in deburring and finishing metal parts like engine components, frame parts, and automotive body panels. The RR4240 can improve both the functionality and appearance of metal parts.

General Manufacturing:

Ideal for handling parts from stamping, laser cutting, and other processes that require finishing before further assembly or coating.

Conclusion:

The RR4240 Double-Head Wet Wide Belt Sander is an essential machine for industries that require high-quality metal finishing. Its powerful dual sanding heads, versatile capabilities, and robust wet grinding system ensure that it is a reliable and efficient solution for deburring, oxide removal, polishing, and edge rounding of various metal parts. Whether you're in the automotive, aerospace, or general metal fabrication industries, the RR4240 will enhance your production process, improve your product quality, and provide long-term reliability.