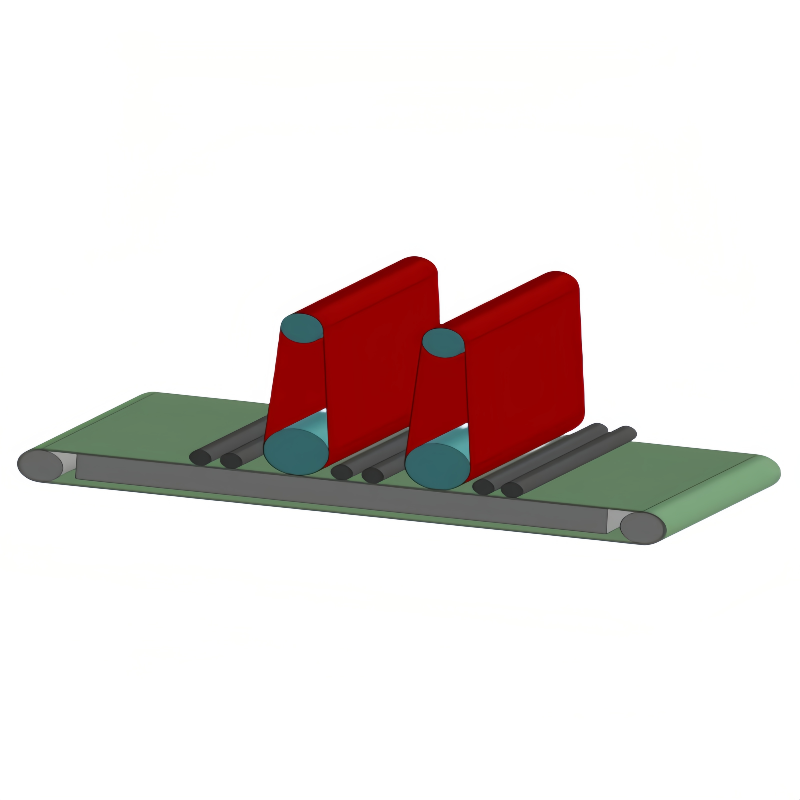

RR4240 Wide Belt Wet Sanding Machine

RR4240 Parts Finishing Machine - Wide-Belt Sander

The RR4240 is a versatile wide-belt sander designed to handle the toughest parts finishing tasks in industrial environments. Whether you're deburring, polishing, or removing oxide layers from metal components, the RR4240 provides high-performance results for a wide range of applications, including stainless steel, aluminum, and carbon steel. Built for high-volume production, this parts finishing machine ensures superior surface quality, efficiency, and minimal downtime, making it a must-have tool for modern manufacturing processes.

Key Features:

Wide-Belt Design:

The RR4240 features a powerful wide-belt sanding system that can handle large surface areas quickly and efficiently. This ensures uniform finishes across large components and maximizes throughput in industrial settings.

Adjustable Sanding Parameters:

The machine allows users to adjust key parameters, such as feed speed, sanding pressure, and belt tension. This ensures precise control over the finishing process, making it suitable for both heavy material removal and light finishing tasks.

Heavy-Duty Construction:

The RR4240 is built with a robust and durable frame that can withstand the rigors of continuous, high-volume production. Its heavy-duty build ensures minimal vibration and maintains high precision, even during long operational hours.

Versatility in Applications:

The RR4240 is highly versatile, capable of processing a wide range of materials, including:

Deburring: Removes sharp edges and burrs from parts, ensuring safe and high-quality components.

Polishing: Achieves smooth, consistent finishes on metal parts.

Oxide Removal: Effectively removes oxide films and scale from metal surfaces, especially after thermal cutting processes.

Edge Rounding: Rounds edges for both safety and aesthetic purposes.

Efficient Dust and Particle Collection:

The machine features an advanced dust collection system, which ensures that harmful particles and debris are safely captured during the sanding process, providing a cleaner and safer work environment.

Ease of Use and Maintenance:

The RR4240 is designed for ease of use, with intuitive controls and an ergonomic interface. Additionally, the machine is engineered for minimal maintenance, reducing downtime and ensuring long-term reliability.

Technical Specifications:

| Specification | Value |

| Max. Working Width | 400mm |

| Max. Working Height | 60mm |

| Abrasive Belt Size | 1520mm × 400mm |

| Main Motor Power | 11 kW |

| Feeding Motor Power | 2.2 kW |

| Feed Speed | 0.5–6 m/min (adjustable) |

| Belt Speed | 15–30 m/s (adjustable) |

| Machine Dimensions (L×W×H) | 2400 × 1800 × 2200 mm |

| Machine Weight | ~2000 kg |

Benefits of the RR4240 Parts Finishing Machine:

High Productivity:

The RR4240’s wide-belt design allows for fast processing of large workpieces, significantly increasing throughput and reducing production time.

Superior Surface Quality:

With its adjustable settings and precision sanding heads, the RR4240 delivers exceptional surface finishes, ensuring that parts meet high-quality standards and are ready for further processing or assembly.

Safety and Cleanliness:

The efficient dust collection system minimizes airborne particles and enhances operator safety. The wet sanding feature helps reduce heat buildup, preventing potential material warping or discoloration.

Flexible and Customizable:

With multiple adjustable parameters, the RR4240 can be customized to meet various metal finishing requirements. From heavy material removal to delicate surface polishing, this machine can handle it all.

Durability and Reliability:

Built with a heavy-duty structure, the RR4240 can withstand continuous operation in demanding industrial environments, offering long-term reliability and minimizing maintenance needs.

Applications:

Metal Fabrication: Ideal for deburring and polishing sheet metal, metal parts, and structural components.

Automotive Manufacturing: Suitable for finishing automotive components like engine parts, body panels, and chassis.

Aerospace Industry: Perfect for processing critical aerospace components that require flawless finishes and tight tolerances.

General Manufacturing: Can handle parts processed by laser cutting, punching, and shearing, providing excellent surface finishes for various industries.

Conclusion:

The RR4240 Parts Finishing Machine - Wide-Belt Sander is a robust, high-performance solution for industries requiring efficient and precise metal finishing. With its advanced features, heavy-duty construction, and customizable settings, it is the ideal tool for applications such as deburring, polishing, oxide removal, and edge rounding. Designed for high-volume production, the RR4240 ensures consistent quality and increased productivity, making it an essential asset in modern manufacturing facilities.